Three frequently asked questions from customers:

l Why your price of drawing die profiler is close to Conoptica?

l How almost all new requirements in China of such systems choose SCreate?

l It’s been 2 decades Conoptica launched drawing die profiler, what new features with SCreate’s profiler?

The answer to above questions we think may be our systems fulfill well the trend of requirements in the industry.

There are two major techniques for reading wire drawing die profile, one is the “Circle Reading” technique invented by Conoptica and only applied by this brand in the past of 20 years, is recognized the best but most expensive solution; another is white-light imaging technique, applied by rest of other brands, mostly applied for somewhere the performance and accuracy is not highly concerned.

Despite of most of drawing die factories understood the investment of good measurement instruments are helping them to improve quality and productivity, and reduce the cost from material saving, the circle reading machine is still too expensive to afford, as the upfront is high and there are yearly charges to pay.

We realized that the more players in the field use good measurement instruments, the better and faster the industries of all wire applications will move towards to. It did inspire us to bring something new to the field that should use circle reading technique and eliminate the need of maintenance by using updated hardware architecture and algorithm. Just two years after we launched such wire drawing die profilers, more than 95% market share switched to us.

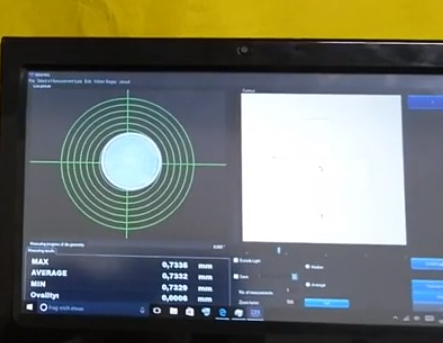

“Circle Reading” technique

Don’t try google or Wiki it, it is the name we internally call it according to the feature of the technique. It is definitely an advanced technology, and very easy to identify if you put a drawing die on measure zone, and see how the profile is read and displayed on screen. It should be displayed as following:

White-light imaging technique

Products using such technique can be identified from the screen displaying as following once you put a drawing die on measure zone:

What do you mean maintenance free to a drawing die profiler?

A drawing die profiler includes lot of precisely components, like optical objectives, laser light source, turntable, worm gear..

In order to make sure the optical objectives keep same physical performance, SCreate doesn’t outsource this very important parts, instead they build an exclusive platform to make every optical objective by themselves. Which makes SCreate different with other brands, every single object quality is under full control by SCreate, thus can ensure our customer all our profilers are performing the same.

Other drawing die measurement systems need routine maintenance on both hardware and calibration every year, which cost users thousands of US dollars to pay every year. Most of the case, the customer service come to your side, open the machine/s, add lubrication and use sample dies to calibrate the machine, that is the money spend for. SCreate exclusively designed oil sealed turntable for their machines, that sealed lubrication in, thus no lubrication is consumed in lifetime using of the profilers.

The light source lens like the door to access measurement, if it is broken, the door is closed. Hundreds of cases we experienced, that when other brands user measuring drawing dies, the die may fall from measure stage and land on the light source lens, then broke the lens.

A slightly but important & exclusive design with SCreate wire drawing die profiler, is we added a NiSi UV filter to protect the light source lens.

Laser light source and other essential parts also get improved by SCreate, if you are interested to learn more about the advantages, here are articles which we break down into details:

http://screate-tech.com/news/8/81.html?lan=en

and

http://screate-tech.com/news/8/84.html?lan=en

ROI of SCreate wire drawing die system

1. Maintenance free and well protected light source

2. High accuracy and repeatability

3. Fulfill the trend of downstream applications’ requirements

4. 24 hours response time in case of any support needed.