Diameter and ovality measuring and control technology is crucial to wire and cable manufacturers, particularly in fine wire products, which requires high precision measurement.

Wire and cable manufacturers invest in-process measuring and control instruments to control products quality and optimize cost. The measurement accuracy of wire diameter plays a crucial role to define a product’s grade.

There are different techniques can measure in production line, or off-line. Most of the measuring instruments are using the method of laser scanning, called laser scan micrometer. Yet, few innovation companies are using the method of laser diffraction technique in the world, that brings advantages laser scan micrometers do not have. There are few know-how manufacturers in the world suppling laser diffraction micrometers, SCreate Technology is proudly on the short supplier list.

We are going to compare and contrast the two measuring methods.

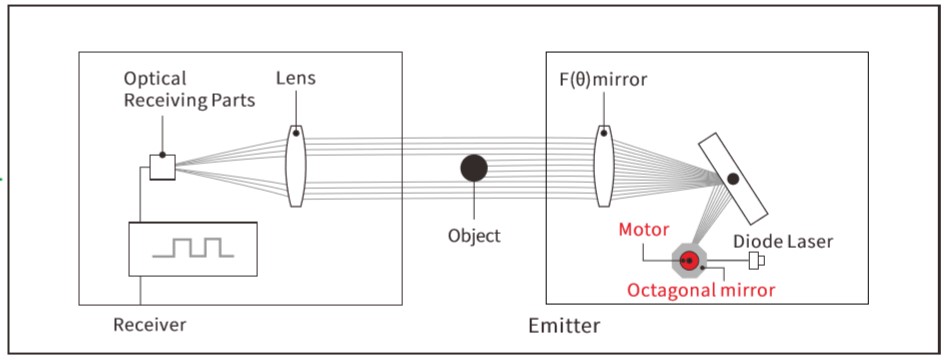

Laser scan micrometer uses a mirror rotating motor inside to strike laser beam, and calculate diameter with the time of laser beam get shadowed by product.

Pro and Con

Pro: Most brands of laser scan micrometers are less expensive than laser diffraction micrometers.

Con:

1. Product life is short, and maintenance is required. As using moving parts drive the precise and accuracy, the performance goes down in a time if without proper maintenance. If you need a professional maintenance for your investment, you have to investment in the extra paid service.

2. Produce laser scan micrometer requires supplier a well control in assembly, alignment and calibration. A less risk way to buy a good product, is go to reputed brands, which also means higher cost.

3. Measuring rate of laser scan micrometer is limited by rotating speed.

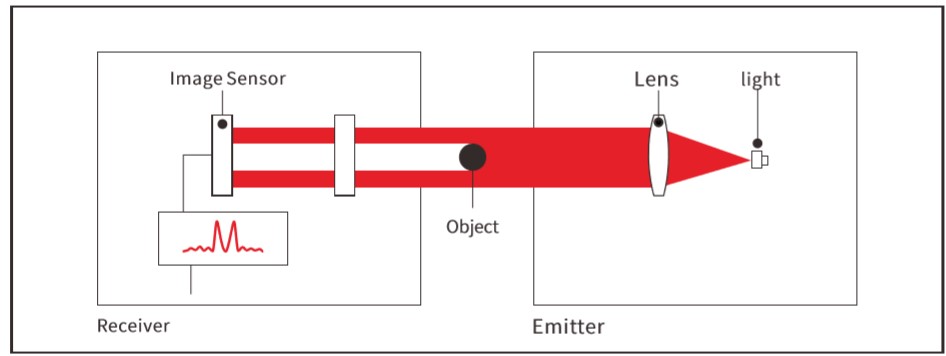

Laser diffraction micrometer is using optical imaging sensors (CCD or CMOS), which provides an extremely high measuring rate. Measurement is calculated by diffraction fringe precisely, for example, SCreate’s laser diffraction micrometers can measure down to 0.005 mm.

Pro & Con:

Pro:

1. Higher precise than laser scan method.

2. No moving parts inside

3. Maintenance free

4. Long durability

5. The higher ROI

Con:

1. Upfront cost is higher than laser scan micrometer

2. Less suppliers of such products