Fast sampling frequency of 46KHz, capable of detecting small defects. Defect image display function, reducing the trouble some of finding defects. 4-axis measurement solution, smaller blind spot.

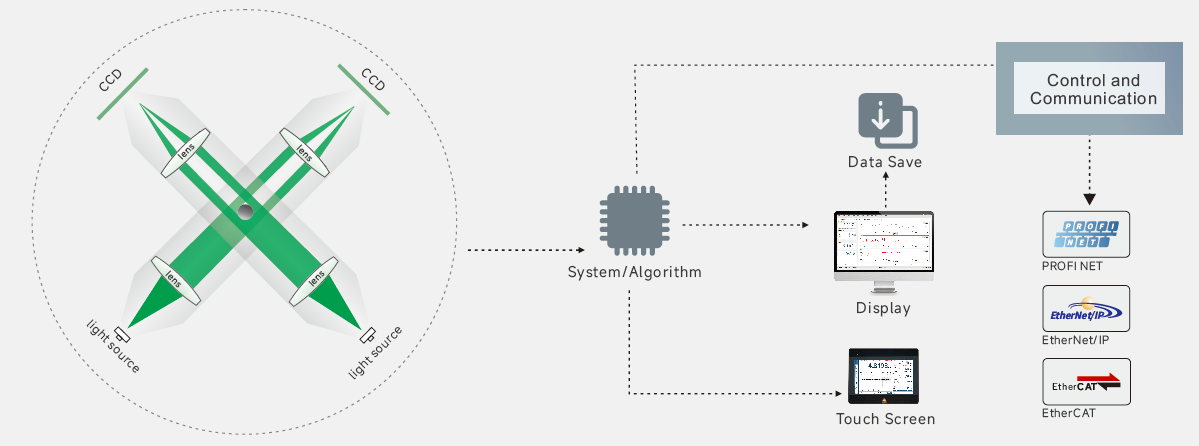

Measurement Principle

When the object is caught by laser beam passed through lens, a bright and dark area will be formed on CCD,then the object dimension will be accurately calculated through software analysis and calculation.

Defect image display function, reducing the trouble some of finding defects

Technical parameter

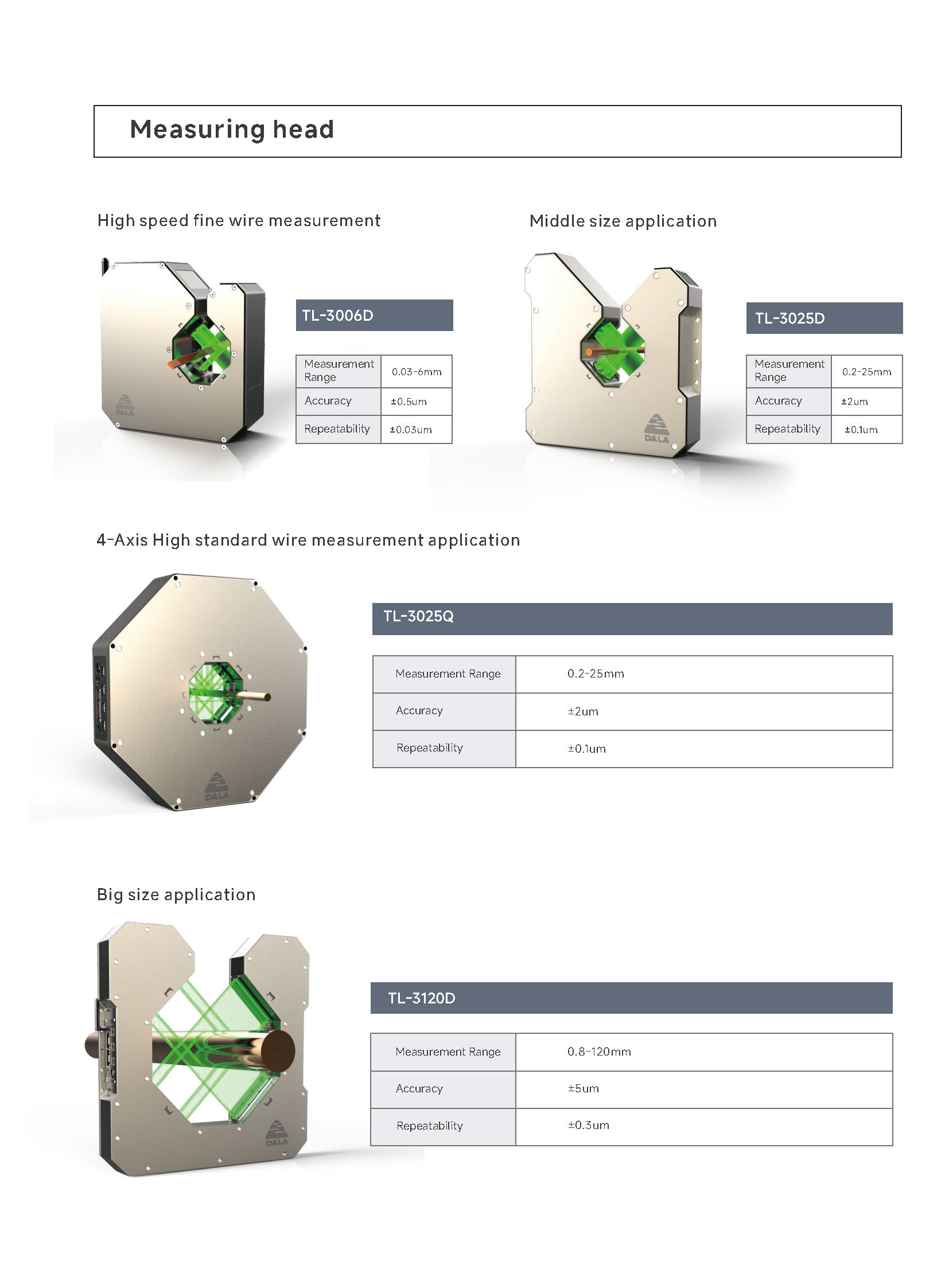

| Model | TL-3006D | TL-3025D | TL-3025Q | TL-3120D |

| Axis | 2-axis | 2-axis | 4-axis | 2-axis |

| Measurement range | 0.01~6mm | 0.2~25mm | 0.2~25mm | 0.8~120mm |

| Repeatability | ±0.03μm(1) | ±0.1μm(2) | ±0.1μm(2) | ±0.3μm(3) |

| Accuracy | ±0.5μm(4) | ±2μm(5) | ±2μm(5) | ±5μm(6) |

| Sampling frequency | 46KHz/Axis | 46KHz/Axis | 46KHz/Axis | 20KHz/Axis |

| Size(L*W*H) | 180*198*60mm | 270*296*60mm | 380*380*68mm | 507*492*65mm |

| Application | round wire, flat wire, transparent wire, hose and bar etc. | |||

| Measurement data | diameter, ovality, width ,thickness ,lumps and necks | |||

| Power supply | 24V ±5%,Max. 75W | |||

| Display | LED | |||

| Communication interface | Standard:RS485 MODBUS RTU、CAN、WIFI Option:PROFIBUS、PROFINET、EtherNet/IP、EtherCAT,etc. | |||

| Electrical port | Default:Digital output (relay), Digital input,Analog input encoder pulse input port. Option: PI feedback control, Analog output(7) | |||

Environmental adaptability | Working Tem. | 0~50℃ | ||

| Working Env. | 20~85%RH(No condensation) | |||

| Brightness | incandescent light, fluorescent lamp 3000lx or less | |||

| Vibrating resistance | 10~55Hz full amplitude 1.5mm in XYZ direction for 2 hours | |||

| Impact resistance | 10G/6ms | |||

| IP grade | IP65 | |||

| Data collection analysis | DMS1000 measurement software system、DS14 ZT display and control system | |||

| Out-of-tolerance alarm | Support | |||

| Transparent mode | Support | |||

NOTE:

(1)Set average number of times to 1150 and measure the ±2σ value of the round standard rod of diameter 10mm at the measurement area center.

(2)For object diameter of 10mm, the measurement accuracy is ±2um when it moves in the center of 8*8mm;

(3)PI feedback control and analog out options shall be ordered at placing device order.

(4) Move φ1mm round rod in the measurement area of 2*2mm and conduct measurement error;

(5) Move φ10mm round rod in the measurement area of 8*8mm and conduct measurement error;

(6) Move φ40mm round rod in the measurement area of 40*40mm and conduct measurement error;

(7) Industrial communication module and PI feedback control module is installed before ex-factory,so notify the demand before placing an order.