Using the principle of telecentric optics, it can measure on-site diameter and surface defects. Multiple terminal applications are available, including mobile devices, PCs, and touchscreens, enabling convenient and real-time data management.

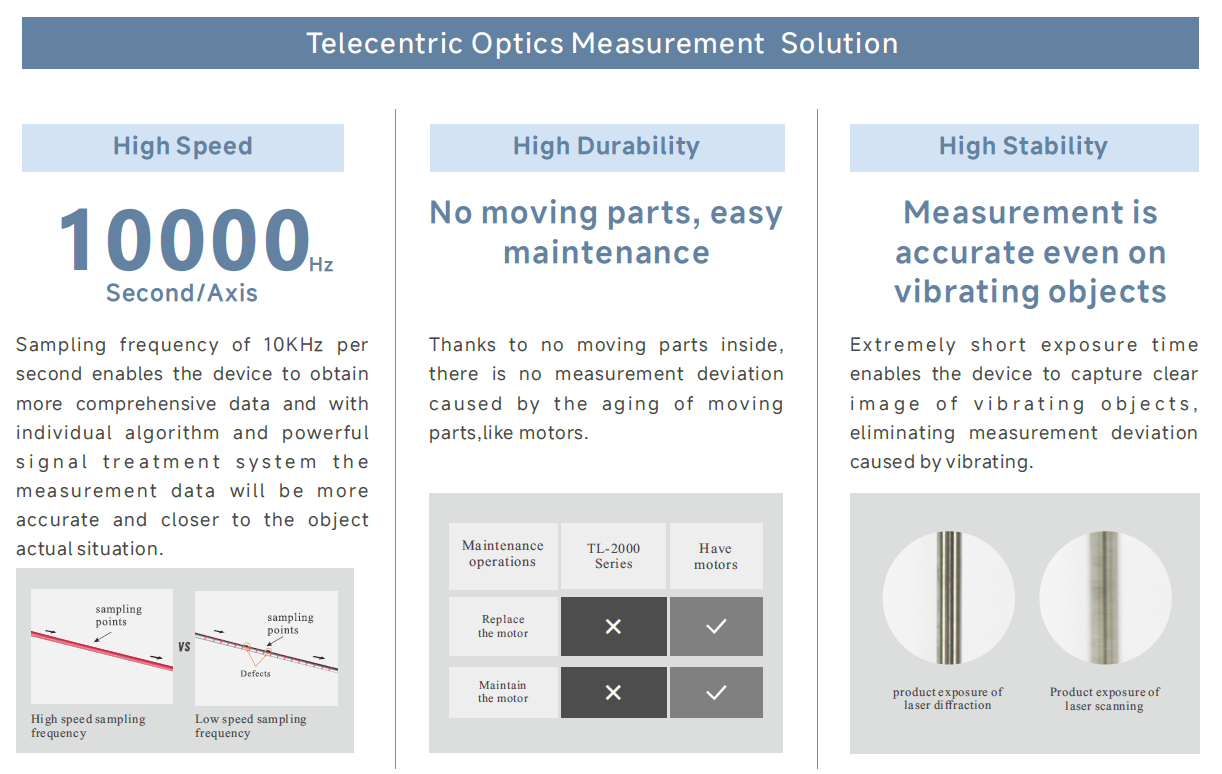

The Combination ofSpeed,Durability and Stability

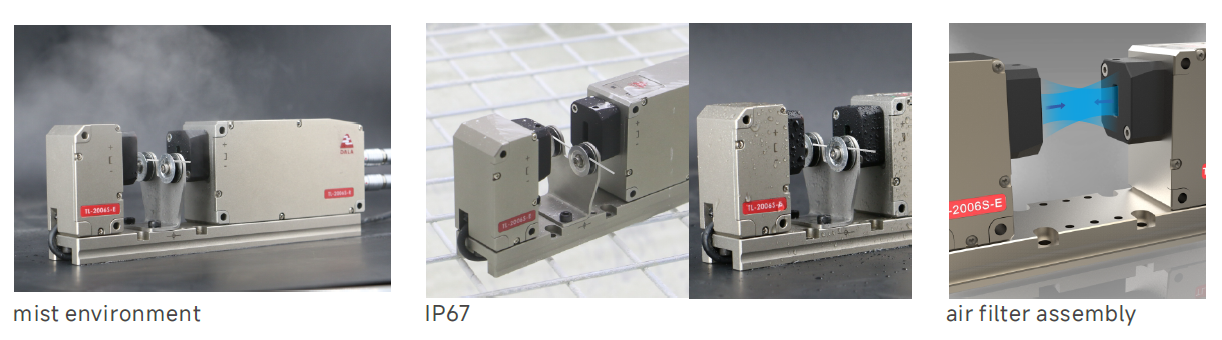

Measurement is accurate even if there is water and dust

Thanks to individual optical system and measurement algorithm, the measurement data of TL2000S Series is still accurate at complex environment.

Environmental adaptability reaches to IP67.Besides,air filter is available to prevent lens front side from contamination ,ensuring measurement data is accurate at various extremely complex environment.

Technical parameter

| Model | TL-2006S | TL-2025S |

| Axis | 1-axis | 1-axis |

| Measurement data | Diameter , Lump&Necks | Diameter &Ovality,Width&Thcikness, Lump&Necks |

| Application field | Round wire ,Transparent wire, Flat wire | Round wire ,Transparent wire, Flat wire |

| Sampling frequency | 10KHz | 10KHz |

| Measurement range | 0.02~6mm | 0.2~25mm |

| Repeatability(1) | ±0.03μm | ±0.1μm |

| Measurement accuracy(2) | ±0.5μm | ±3μm |

| Working power | 24V ±5% ,Max. 75W | 24V ±5% ,Max. 75W |

| Display | LED | |

| Communication port | Default:RS485 MODBUS RTU、WIFI | |

| Electrical port | Default:Digital output (relay), Digital input,Analog input encoder pulse input port. | |

Environmental adaptability | Working Environment:0~50℃ Working Environment:20~85%RH(No condensation) Working environmental brightness:Brightness of working environment Incandescent light, fluorescent lamp 3000lx or less Vibrating resistance:10~55Hz full amplitude 1.5mm in XYZ direction for 2 hours Impact resistance:10G/6ms | |

| Water-proof grade | IP67 | |

| Data collection analysis | DMS1000 measurement software system、DS14 ZT display and control system | |

| Out-of-tolerance alarm | Support | |

| Transparent mode | Support | |

NOTE:

(1)Set average time to 0.1s and measure the ±2σvalue of the φ1mm round rod at the measurement area center;

(2)Set average time to 0.1s and measure the ±2σvalue of the φ10mm round rod at the measurement area center;

(3)Move φ1mm round rod in the measurement area of 2*2mm and conduct measurement error;

(4)Move φ9mm round rod in the measurement area of8*8mm and conduct measurement error;Move φ18mm round rod in the measurement area of4*4mm

and conduct measurement error;