SCreate DALA's all new CV-2000 series is an ideal system for object size measurement and continuous in-line surface defects inspection, meeting the current market demand for in-line surface quality inspection of extruded products such as wires,hose and cables. It is particularly suitable for surface quality inspection of enameled copper wires, wires and cables, hose, etc. It can detect defects such as burns, missing coating, scratches, lumps & necks, wrinkles, tears,colour difference, bubbles, cracks, holes,etc.

Measurement principle

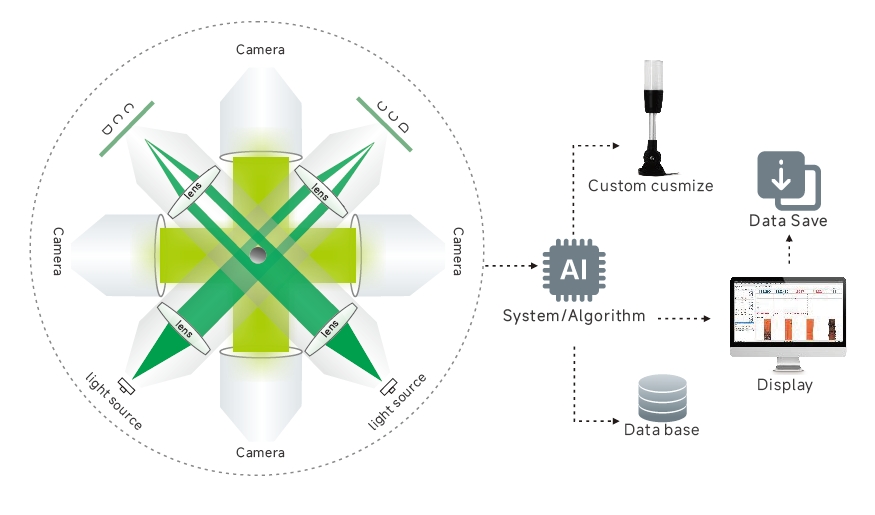

Surface quality inspection systems consist of high-resolution cameras and high brightness illumination light sources,forming a dark field or bright filed machine vision to capture the image of high speed movement object.

Multiple cameras achieves 100% surface image acquisition,and then use pre-trained machine to learn and process collected images so as to identify and clarify various defects.

Key characteristics

⁕ One system can achieve dimensional measurement and continuous surface

⁕ 2-axis high speed dimensional measurements and necks &lumps detection

⁕ Multiple machine learning models reduces the missed detection rate and false detection rate

⁕ Support defects classification function

⁕ Automatic focusing ensures clear image,small defects are detectable.

⁕ Ultra-bright light source external independent module design, flexible configuration, easy maintenance

⁕ Compact design better for industrial field applications

⁕ Customize alert function, alert levels also can be set based on defects type and defects size.

⁕ Storage of dimensional information, defects size, defect images,and statistics data etc in database

Technical parameter

| Model | TL-3025Q(1) |

| Measurement range | 0.2~25mm |

| Axis and frequency | 2-Axis,46KHz/Axis |

| Measurement type | Round wire: diameter, ovality, surface quality Flat wire: width, thickness ,surface quality |

| Dimensional accuracy(2) | ±2μm |

| Minimum defect height | ±10μm |

| Minimum defect size | Related to cameras, optical lens and production line speed , minimum to size of 0.05mm can be achieved |

| Power supply | 24VDC ± 5%, Max. 84W |

| Max wire speed | Related to cameras and optical lens configuration as well as minimum defects size and colour difference inspection . related to measurement requirements , need on site adjustment. |

| Surface defects missing rate(3) | <1% |

| Surface defects detection false(3) | <1% |

| Electrical interface | RS485 MODBUS RTU、CAN、UDP |

| Weight | 12.5kg |

| IP grade | IP54 |

NOTE:

(1)More new products will released soon;

(2)Move φ10mm round rod in the measurement area of 8*8mm and conduct measurement error;

(3)Related to measurement requirements , need on site adjustment.